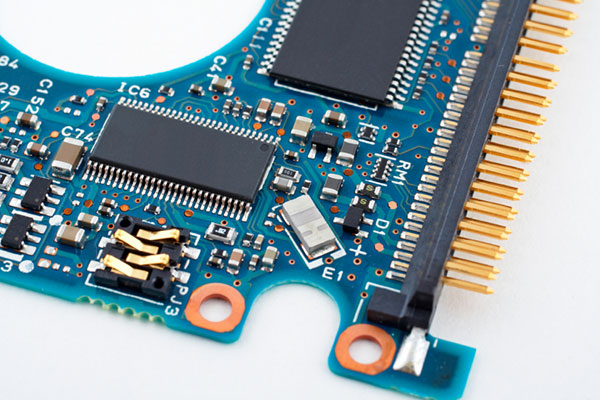

Our solutions for electronic boards

- Defluxing of single ou double sided SMT or THT electronic boards,

- Misprints,

- Bare boards prior chip bonding and/or wire bonding,

- Conformal coating stripping,

- Dust cleaning (after market).

Developed to meet the highest requirements in terms of quality and ionic contamination, our immersion process offers a concrete alternative to the ultrasonic cleaning (often forbidden on electronic boards) and to the spray in air cleaning (that often generates shadowing effect).

Our SUI (Spray Under Immersion) technology combines permant chemistry exposure and global cleaning action all over the boards, thus eliminating any possible shadowing effect.

Associated to our wash solution patented filtration and to a closed-loop rinsing process, our NC25 range will allow you to perform high precision cleaning for the lowest running cost.

And finally, because the industry is always looking for effective means of supervising their production, MBtech has developed its own traceability system adapted to the NC25 range.

The NC25Manager goes beyond the SPC solutions (supervision of the machine only) and gives the possibility of having a real monitoring process for every single board produced.

NC25 is available in 3 versions to meet your production volumes:

All models come with a built in automatic transfert system from tank to tank.

For large and heavy electromechanical assemblies, MC200+ will answer your needs thanks to its heavy duty basket.

- In addition to our range of products, we also offer our customers the entire range of contaminometer from Gen3Systems®. Thanks to their high accuracy, these devices make possible to confirm your board cleaning process repeatability.